WHY IK SPORTS?

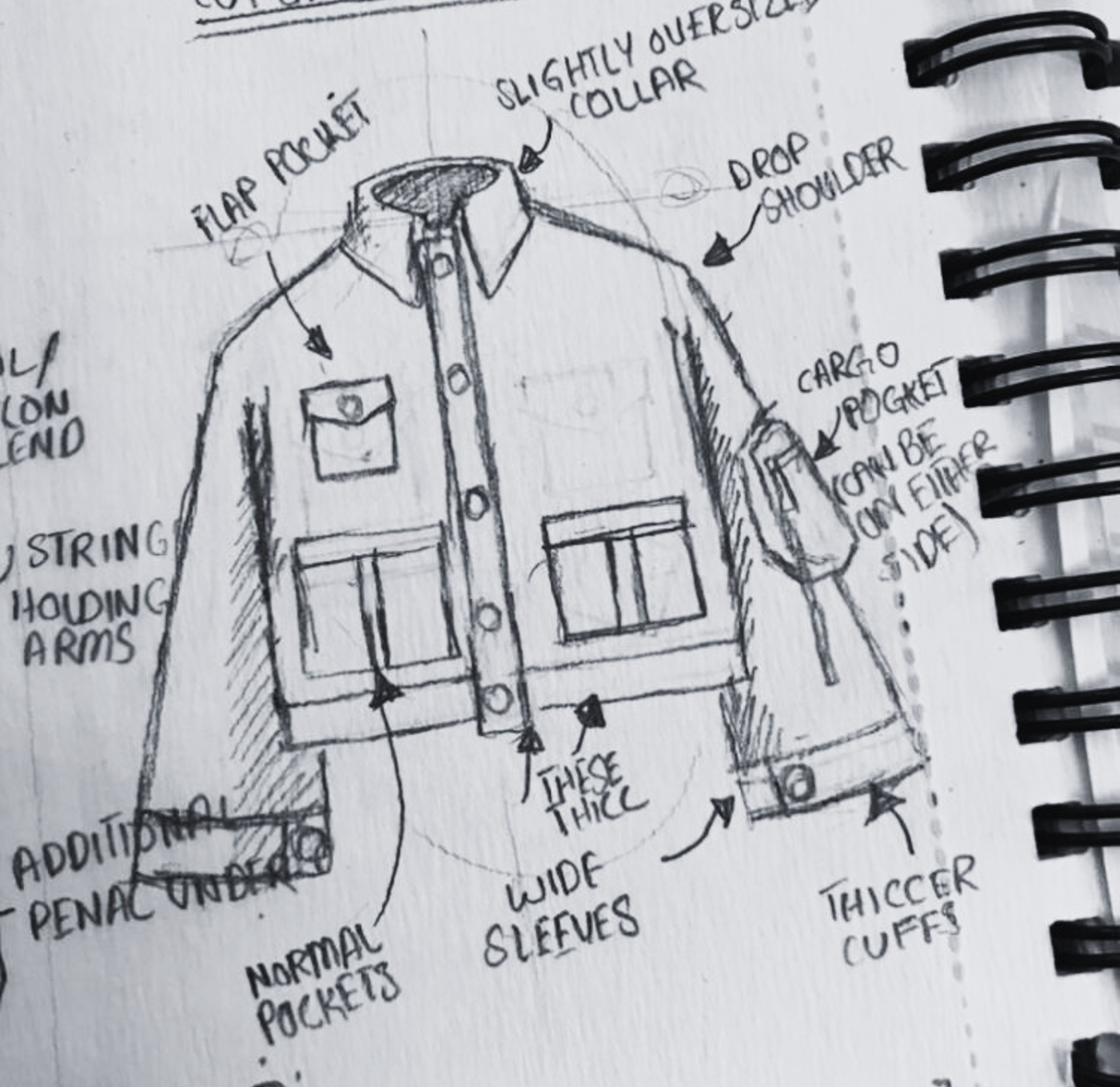

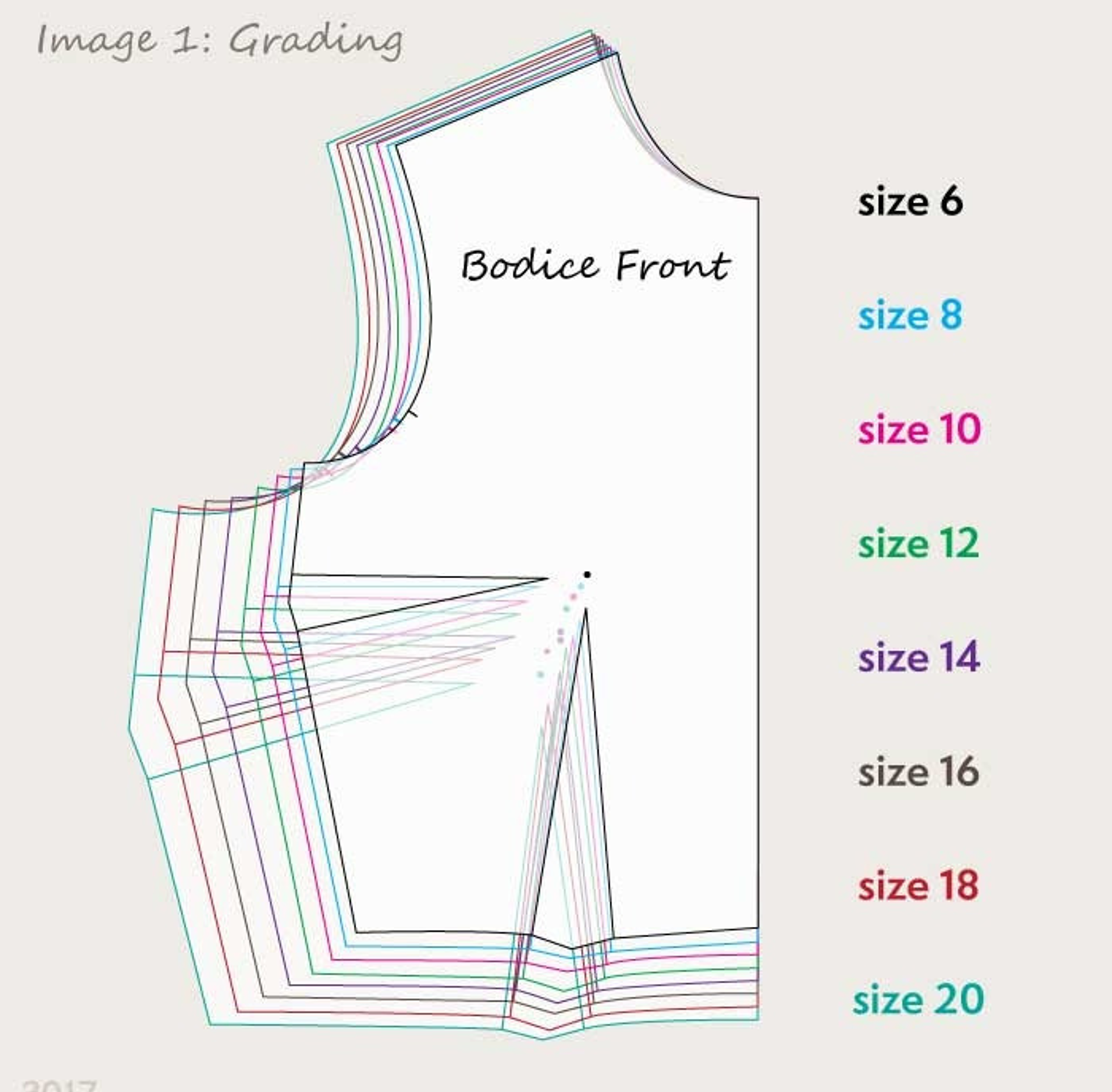

We specialize in crafting personalized team wear, clothing, socks, bathing textiles, and gloves, tailored to meet the demands of any adventure. Drawing from over a decade of expertise in manufacturing, design, and branding, we integrate cutting-edge fabric advancements and printing techniques to produce exclusive apparel for brands. Start crafting your custom-branded attire today.

Our Clients

PROCESS

CONTACT US

INQUIRY FORM

Send IK Sports custom sportswear manufacturer a request in a few moments. Write all the details and quantities you need, we will reply as soon as possible!